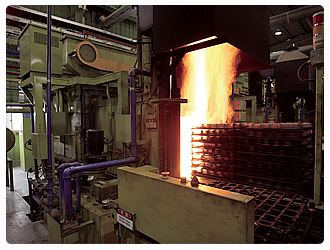

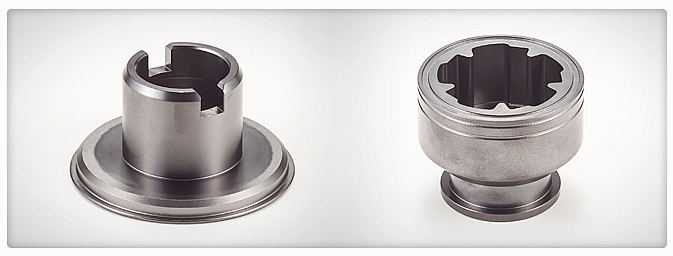

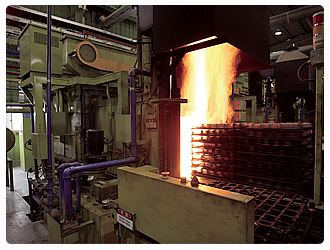

Case-hardening process that introduces nitrogen into the surface of a solid ferrous alloy by holding the metal at a suitable temperature (below Ac1, for ferritic steels) in contact with a nitrogenous gas, usually ammonia. Does not require quenching for production of a hard case.

EXPECTED PROPERTY

- + Less distortion and deformation

- + White layer gives corrosion, wear and fatigue resistance

- + Better fatigue strength

- + Remain inner toughness

- + Workable with low carbon steel

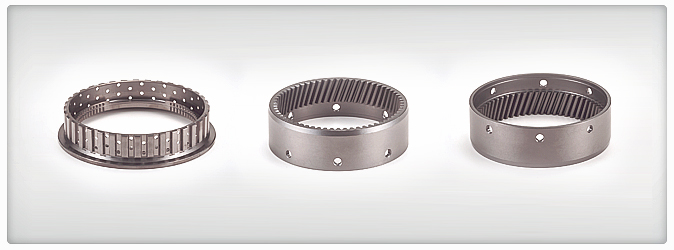

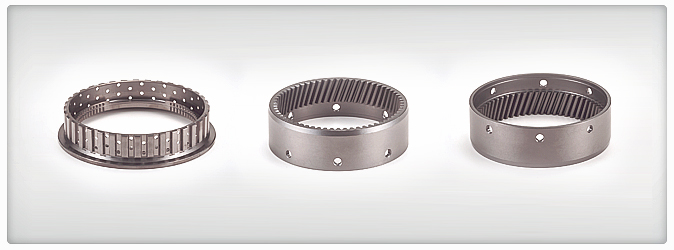

Application

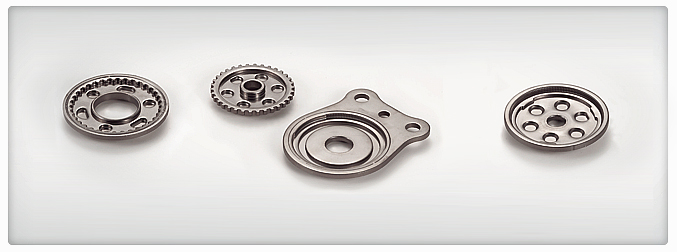

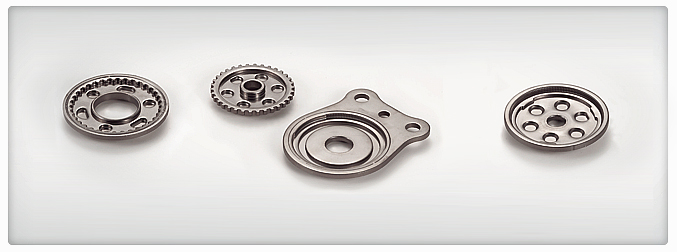

- + Automotive (plates, gears, parts etc.)

- + Die Casting / Plastic injection molds

- + Ship & aircraft parts

- + Industrial, electric parts

- + Hot forging molds

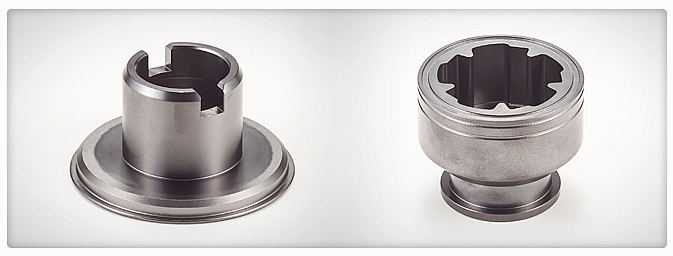

- Traditional case-hardening process in which carbon is dissolved in the surface layer of a low-carbon steel at a temperature sufficient to render the steel austenitic, followed by quenching and tempering to form martensitic microstructure.

- Carbonitriding hardens surface of steel by diffusing carbon and nitrogen simultaneously into steel in carburizing atmosphere with ammonia gas at around 850`c, lower than typical carburizing temperature.

- It offers several advantages over carburizing, including low distortion, greater resistance to softening during tempering and fatigue strength.

Operational property

- + Selective hardening

- + Maintain inner toughness & wear, fatigue enhancement where high frequency heated

- + Stable carburized depth

- + Less oxidation & decarbonizing

- + Less deformation, less size scattering

Application

- + Deform sensetive Automotive parts

- + Industrial parts

- + Vessel & aircraft parts

- Oxynitriding forms Fe3O4 at the outer layer over compound layer

EXPECTED PROPERTY

- + Wear ,fatigue resistance

- + Fe3O4 gives better corrosion resistance

- + Product color(Black & Blue)

- + Alternative for hard Cr plating

- + Workable with low carbon steel

APPLICATION

- + Automotive (plates, gears, parts etc.)

- + Die Casting / Plastic injection molds

- + Industrial, electric parts

- + Mold & Dies

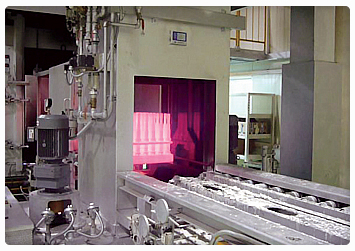

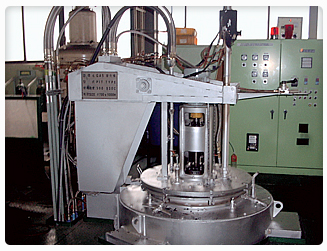

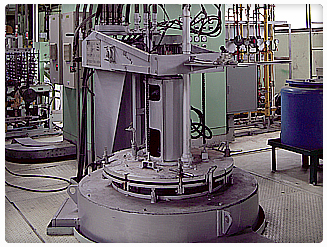

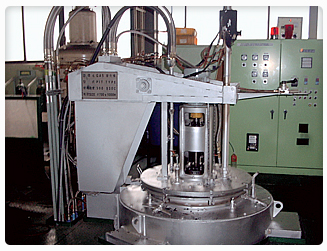

- Ion nitriding extends conventional nitriding processes using plasma discharge physics. In a vacuum, high-voltage electrical energy is used to form a plasma through which nitrogen ions are accelerated to impinge on the work piece. Ion bombardment heats the product, cleans the surface and provides active nitrogen.

Plasma Nitroxidation

Operational property

- + Precise control on diffusion layer

- + Precise temp control offers deformation stability

- + Heat treating stainless

Application

- + Automotive (plates, gears, parts etc.)

- + Die Casting / Plastic injection molds

- + Industrial, electric parts

- + Mold & Dies

Feature

- + Continuous Nitriding & Oxidation in same process

- + Oxidation with No change in surface roughness

- + Enhanced lubrication characteristic

- + Corrosion, fatigue resistance

![Plot No. 126, Samathuvapuram, Mappedu, Ulundai[Post] Thiruvallr [TK && Dist] Tamilnadu, India Tel. +91-44-2769-9814 COPYRIGHTⓒ 2013 DONGWOO SURFACETECH(INDIA) Pvt.Ltd. ALL RIGHTS RESERVED.](../images/common/copyright.gif)