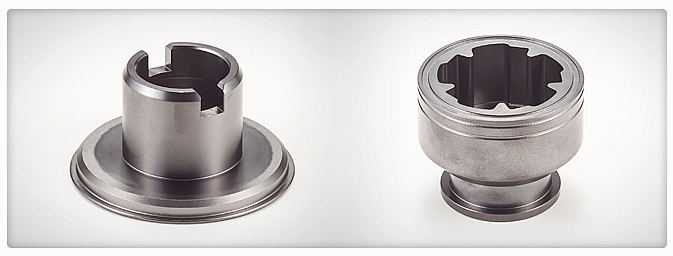

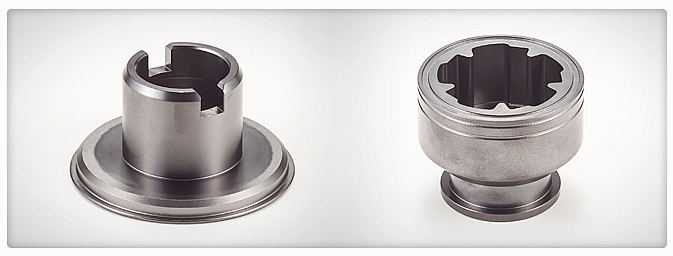

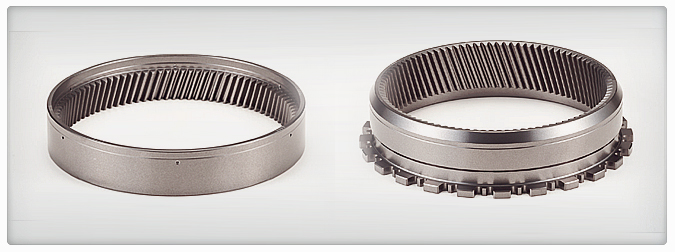

- Traditional case-hardening process in which carbon is dissolved in the surface layer of a low-carbon steel at a temperature sufficient to render the steel austenitic, followed by quenching and tempering to form martensitic microstructure.

- Carbonitriding hardens surface of steel by diffusing carbon and nitrogen simultaneously into steel in carburizing atmosphere with ammonia gas at around 850��C lower than typical carburizing temperature.

- It offers several advantages over carburizing, including low distortion, bigger resistance to softening during tempering and fatigue strength.

HARDNESS PROFILE BY CARBON CONTENT

EXPECTED PROPERTY

- + Enhanced Wear & Shock resistance

- + Uniform case depth & Easy control

- + Carbonitriding

- - Less distorsion with lower process temp

- - Lower carbon steel(plates) enable

APPLICATION

- + Automotive parts

- + Industrial parts

- + Ship & aircraft parts

- Traditional case-hardening process in which carbon is dissolved in the surface layer of a low carbon steel at a temperature sufficient to render the steel austenitic, followed by quenching and tempering to form martensitic microstructure.

- Carbonitriding hardens surface of steel by diffusing carbon and nitrogen simultaneously into steel in carburizing atmosphere with ammonia gas at around 850℃ lower than typical carburizing temperature.

- It has several advantages such as low distortion, bigger resistance of softening during tempering, and fatigue strength over carburizing.

HARDNESS PROFILE BY CARBON CONTENT

EXPECTED PROPERTY

- + Enhanced Wear & Shock resistance

- + Uniform case depth & Easy control

- + Carbonitriding

- - Less distorsion with lower process temp

- - Lower carbon steel(plates) enable

APPLICATION

- + Automotive parts

- + Industrial parts

- + Ship & aircraft parts

- Non-equilibrium, boost-diffusion carburizing process in which steel being processed is austenitized in a rough vacuum, carburized in a partial pressure of hydrocarbon gas, diffused in rough vacuum and then quenched with gas.

HARDNESS PROFILE BY CARBON CONTENT

EXPECTED PROPERTY

- + No oxidation layer

- + High density carburazing

- + Enhanced fatigue strength

- + Clean(bright) product

- + Easy carburizing in small holes

- + Clean environment

APPLICATION

- + Automotive parts

- + industrial parts

- + ship & aircraft parts

- + Tool parts(SKD, SKH etc.)

- + Brazing

![Plot No. 126, Samathuvapuram, Mappedu, Ulundai[Post] Thiruvallr [TK && Dist] Tamilnadu, India Tel. +91-44-2769-9814 COPYRIGHTⓒ 2013 DONGWOO SURFACETECH(INDIA) Pvt.Ltd. ALL RIGHTS RESERVED.](../images/common/copyright.gif)